Center of Excellence

About Center of Excellence

Siemens, in collaboration with the Government of Gujarat, has established Center of Excellence (COE) at various Government Engineering Colleges across the state. One such COE is located at the Government Engineering College in Patan. This centre focuses on Industrial Automation and comprises nine specialized laboratories equipped with advanced machinery and licensed software, including NX Academic, CAD, CAM, Technomatix, and Rob Cad. The laboratories are designed to enhance the skills of engineering students and professionals in areas such as Product Design, Validation, and Electrical Machine Automation.

Read the Detailed COE Course Plan here : COE Course Plan

These Center of Excellence play a crucial role in bridging the gap between academia and industry, ensuring that students and professionals in Gujarat have access to the latest technological advancements and training opportunities. Center of Excellence (COE) Patan provides specialized laboratories equipped with advanced tools and software to train students and professionals in automation.

Vision

Mission

Additive Manufacturing (3D Printing) Lab

Explores rapid prototyping and advanced manufacturing techniques. Equipped with SST 1200ES 3D printers for additive manufacturing, this lab facilitates rapid prototyping and the creation of complex geometries.

Electrical Automation Lab

Deals with smart grids, energy distribution, and automation of electrical machines.

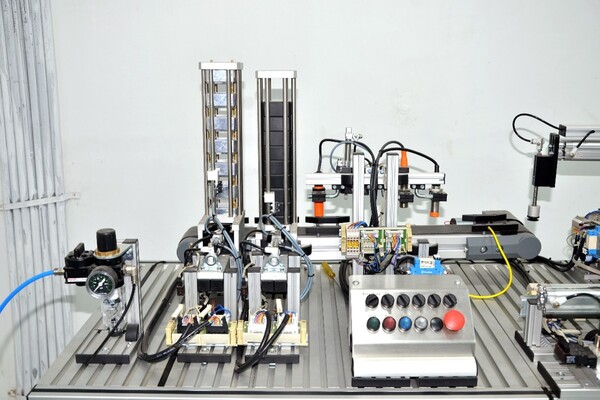

Mechatronics and Robotics Lab

Focuses on robotic automation, motion control, and mechatronics system design. Provides training with modular automation production systems (MAPS 6S), Siemens S7-1200 PLCs, and diagnostic kits, focusing on the integration of mechanical, electronic, and control systems.

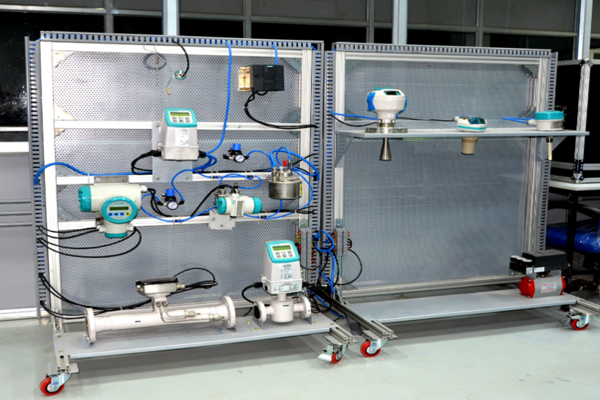

Process Instrumentation & Control Lab

Covers sensor technology, control systems, and industrial process monitoring.

Computer Integrated Manufacturing (CIM) Laboratory

Integrates CNC milling and turning machines, automatic guided vehicles (AGVs), industrial robots, and vision inspection systems to simulate and study automated manufacturing processes. Features 2-axis CNC turning machines with 8-tool turrets and 3-axis CNC vertical milling machines with automatic tool changers, providing practical training in CNC machining operations.

Product Design and Validation Lab

Focuses on CAD, CAE, and simulation technologies using Siemens NX software. Employs Siemens NX for comprehensive training in product design, modeling, and simulation, enhancing skills in creating and validating complex engineering designs.

CNC Programming Laboratory

Equipped with SINUMERIK 808D and 828D controllers for both turning and milling operations, this lab focuses on numerical control programming and simulation of toolpath generation.

Advanced Manufacturing Lab

Covers CNC programming, virtual machining, and manufacturing process automation. Utilizes Siemens NX software for training in advanced manufacturing techniques, including digital manufacturing and virtual machining simulations.

Industrial Automation Lab

Provides hands-on experience with PLC, SCADA, HMI, and industrial networking.

Sub-Objectives

Committee Members

Dr. K. V. Patel Coordinator

Dr. P. D. Patel Member