Mechanical Engineering

Mechanical Engineering

Our strong academic performance in high school enables you to pursue a range of educational opportunities. One avenue you'll want to explore is mechanical engineering. Studying mechanical engineering at Government Engineering College Patan will equip you with a broad education, preparing you for a variety of career paths graduation and providing a solid foundation for continuing education. Mechanical engineering encompasses many areas. In short, anything that involves the design and or manufacturing of mechanical, thermal or electronic devices and or processes falls entrepreneurs, chief engineers, astronauts, faculty, physicians and patent attorneys, among other occupations. The field includes activities such as designing, developing, manufacturing, managing, researching and controlling engineering systems and their components.

Total Intake

Faculties Member

Labs And Workshops

Annual Placement

Vision

To create a centre of excellence for imparting education in mechanical engineering field to meet the current and future challenges of technological and sustainable development.

Mission

To build enabling environment for excellent teaching, learning and research in order to produce entrepreneurs and innovators in the field of Mechanical Engineering for sustainable improvement.

To impart adequate fundamental knowledge, technical and soft skills to students.

To develop Mechanical Engineering solutions for the problems of industry and society.

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

To prepare graduates with a technical knowledge of mathematical, scientific, engineering, technology, management, humanities and various other interdisciplinary subjects for a successful career.

Graduates will apply the knowledge of Mechanical Engineering to solve real Engineering problems for sustainable development.

To inculcate graduates with leadership skills with high level of integrity, Professional personality and ethical values.

To equip graduates with modern tools, technology and advanced software for deliberating engineering solutions.

PROGRAM SPECIFIC OUTCOMES (PSOs)

Apply the advanced software skills to Model, simulate, analyze and optimize Mechanical systems and Processes

Acquire technical and managerial skill for innovative activities.

Automation in Manufacturing Lab

Basic Mechanical Engineering

Computer-Aided Design (CAD) Lab

Computer Aided Manufacturing

The Dynamics of Machinery Lab

Engineering Graphics & Design

Fluid Mechanics and Hydraulic Machines Laboratory

I C Engine Lab

Material Science and Metallurgy Laboratory

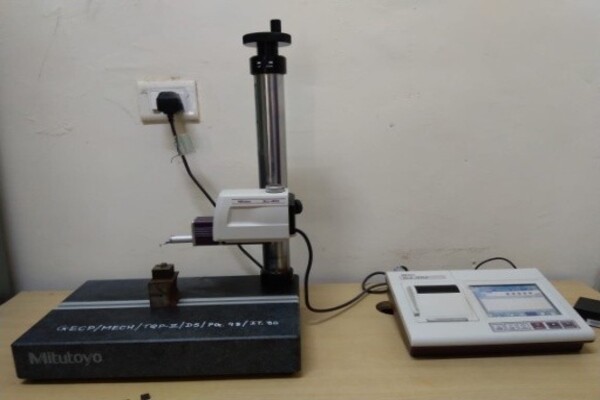

Mechanical Measurement and Metrology Laboratory

Renewable Energy Engineering Laboratory

Workshop/Manufacturing Process Laboratory

Teaching Staff

- Designation: Professor

- Area Of Interest: cad, cam, metal forming, automobile engg, manufacturing engg

- Designation: Assistant Professor

- Area Of Interest: Jet propulsion and gas turbine

- Designation: Assistant Professor

- Area Of Interest: Mechanical Engineering

- Designation: Assistant Professor

- Area Of Interest: Parametric Optimization, Non Conventional Machining Processes, Finite Element modelling.

- Designation: Assistant Professor

- Area Of Interest: I. C. Engines & Automobile

- Designation: Assistant Professor

- Area Of Interest: Solar Thermal, Solar Photovoltaic, IC Engine

- Designation: Assistant Professor

- Area Of Interest: Design, Dynamics and Manufacturing

- Designation: Assistant Professor

- Area Of Interest: POWER PLANT ENGINEERING

Non-Teaching Staff

MOOC Sensitization And Registration (Mechanical & Civil)

No Activities Available

| Achievements |

|---|

Dr. Hitesh N. Panchal, Successfully Completes AICTE–QIP PG Certificate Programme

|

Mr. Aakash Kumar, Mechanical Student Wins 1st Place in “Igniting Young Minds – Power and Energy Quiz” at Ganpat University

|

Mr. Ankitkumar Vaniya, Alumnus Mechanical Engineering 2012-2016, UPSC Civil Services Examinations Mains - 607th Rank

|

Dr. Hitesh N. Panchal Listed Among Top 2% Scientists Worldwide (2025)

|

Meet Chaudhry, 8th Sem Mechanical Represents GTU in West Zone Inter-University Basketball Championship

|

Rajbhar Dipakkumar, Wins Gold in Best Physique at GTU Sports Spirit

|

Meet Chaudhry, Wins Bronze at 36th National Games in Netball

|